BYTEC started the 03-01-2003 as a company for engineering consultancy based on finite element simulations of products and processes (design optimization, quality control). It was decided in 2017 to nominate the pensioned professor Hugo Sol as research adviser and to focus on the development of an instrument for the identification of the material properties (with a focus but not exclusively on composites). The instrument is called “the Resonalyser”, derived from its purpose to analyze measured resonance frequencies of test samples.

History of the Resonalyser development

•1986: Invention of the Resonalyser concept (PhD Hugo Sol)

•1986 –2017: Many publications and Research projects involving the Resonalyser concept at the University of Brussels (VUB)

•2017-2019: Development of a portable Industrial version of the Resonalyser

•2020-2022: BYTEC starts an ICON project with the VUB, supported by SIM and VLAIO, for the development of an automated Resonalyser in a climate chamber (-80°c till 160°C) to enable measurement of the temperature dependency of thermoplastic composites.

Aluminum

Steel

Magnesium

Composites

Polymer Resins and Additives

Fibers: Glass Fibers, Carbon Fibers

Comingled Yarns

Short Fiber Compounds, Long- fiber-reinforced Compounds, Molding Compounds

Unidirectional Tapes

Reinforcement Materials

Laminates and Sheets

Fabrics

Profiles and Inserts

Fillers and Reinforcers

Testing equipment

Identification of Engineering constants of composites:

In 2022 several specific composite and orthotropic materials were identified for different Clients:

Wooden panels (influence of moisture on long term degradation of wooden panels used in building constructions), composite sandwich panels (transport industry), detection of anisotropy in rolled steel plates, thermoplastic composite sheets for the aerospace industry.

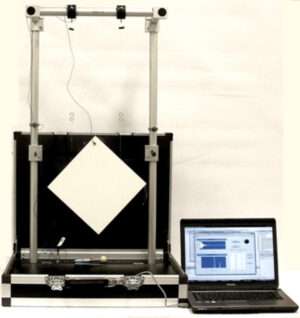

Selling of the “Resonalyser” test instrument: The Resonalyser is a disruptive instrument based on computer intelligence that can identify complex orthotropic engineering constants (real elastic part and damping part) by vibration measurements on test plates. The focus is on composite materials (UD, Bi-directional, textiles reinforcements, … )

Test service:

Identification of the orthotropic engineering constants of composites :

Young’s modulus in the 1-orthotropic direction E1

Young’s modulus in the 2-orthotropic direction E2

Poisson’s ratio v12

In-plane shear modulus G12

Identification of the stiffness and transverse shear moduli (G13, G23) of sandwich panels

Fast and accurate identification of material properties

mainly composites materials

Resonalyser instrument

finished

Distribution companies for Resonalyser instruments in Germany, France, UK and Holland

Contact details

Jun Gu

+32 494 487901

www.Resonalyser.com