Sadechaf has over 40 years of expertise in UV Curing Technology. We offer total customer care for our customer’s UV Curing System. We have more than 5000 different lamps and spare parts of the most renowned UV manufactures so we can secure the efficiency and continuity of your operation. Our engineers design an optimal solution for every UV challenge and our own technical team takes care of the installation, the startup, the maintenance and repair of your UV Systems and UV Equipment.

Curing of UV resin layer of sills and frames

We helped a client with developing extreme light weighted isolation sills, window frames and door frames. For the sill and frames they use a isolation foam core with a UV resin layer. We were responsible for the installation that cures the materials so that frames become stiff and less breakable. Ideal for the construction industry that demands stronger and more energy efficient products.

Natural stone looking product, light weight, insulated product, strong and wear- resistant, easy editable

UV resin and foam core

UV Curing system with 3 lamps

Finished

Comprifalt

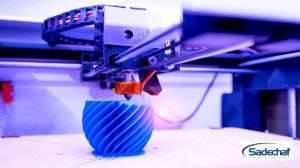

Fiberglass and carbon fiber composite parts can be cured using ultraviolet (UV) light.

UV curing dramatically reduces the curing time of composite parts from hours to minutes. In addition, UV curing provides a more consistent and controlled process compared to existing catalyst processes which can vary depending on the humidity and temperature. UV curing is especially advantageous for open molding, filament winding, pultruding, and 3D printing of mass produced products or low volume high value parts where quality, consistency, and high production rates are important.

Sadechaf selects, installs and maintains for its customers the right UV system suited to their needs. Our extensive maintenance services and range of lamps and spare parts of the most renowned UV manufacturers secure the efficiency and continuity of your operation.

Manufacturers of composite products should evaluate UV curing as a way to increase production and lower styrene emissions.

RV and truck panels, and other open molded parts

Windmill blades

SCBA and other filament wound tanks

Pipes, masts, poles and other cylindrical filament wound parts

Pultruded fiber optic strength member rods

Contact details

Mathijs Verwulgen

0031 (0)6 19 03 27 23

www.sadechaf.eu

Turnhout 2300

Belgium