Sirris is a non-profit organisation composed of more than 150 employees and based in 8 sites in Belgium. With more than 60 years of experience, Sirris offers individual support at every step along the way, from the drawing board stage to the prototype development and pilot tests for finished products. Everything that companies need to develop, industrialise and commercialise their innovating products is available in the form of:

- Experts in all the involved domains, for example: design of smart, light, micro products; mechatronics; data & software engineering

- A large network of industrial and academic contacts

- Several labs and shopfloors with advanced equipment

- Continuously updated knowledge about technologies and processes

- Design

- Simulation

- Composites

- Comingled Yarns

- Short Fiber Compounds, Long-fiber-reinforced Compounds, Molding Compounds

- Unidirectional Tapes

- Reinforcement Materials

- Laminates and Sheets

- Profiles and Inserts

- Fillers and Reinforcers

- Presses

- Injection Molding

- Combined Processes

- Tooling

- Automation

- Prototyping

- Manufacturing

- Assembly

- Virtual testing

- Testing equipment

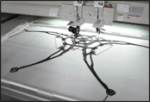

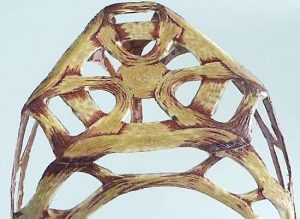

Tailored Fibre Placement in TP Composites: The project focused on material developments and more particularly on hybrid yarns with tailored properties. Demo parts were designed, manufactured and consolidated in a vacuum bagging process. Specific toolings were realised by processes such as incremental sheet forming.

- Advantages: Orientation of fibres according to stress state

- Materials: Hybrid yarns

- System and process: Tailor Fibre Placement, vacuum bagging, incremental sheet forming

- Further details (weight, surface quality, costs): Very low weight for high strength

- Development status: Completed

- Development partners: FGK, Fraunhofer IWU, IPF, Sirris

Design and Simulation

- Mechanical/Structural simulation

- CFD simulation

- Topology optimisation

Materials

- Ability to deal with resins, fabrics, fibres reinforced polymers

- Main focus on thermoplastic composites processing but actions on thermoset materials also available

- Large interest in Hybrid structures

Machinery and Tooling

- Numerical lathe, (micro) milling machines, (micro) EDM machines

- Freeform Hybrid 3D printing

Production

- Capabilities in terms of prototyping, manufacturing small series to validate a concept

- Autoclave and special oven (400°C), vacuum bag, thermoforming, injection molding, RTM

Process Optimization and Consulting

- Addition of smart functions to machines, integration of augmented reality, operator assisted manufacturing

Great interest in hybrid structures, 3D printing of large & complex shapes, ….

Contact details

Garray Didier

Principal Engineer

+32 498 91 93 31

Didier.Garray@sirris.be

Company details

https://www.sirris.be

4102 Seraing

Belgium